‘A giant leap forward’: How Implican’s technology will make surgery safer

Implican is developing an innovative technique to promote primary wound healing after colon and rectum surgery. Initial test results are promising. With help from NOM and NextGen Ventures, the company hopes to start preclinical and clinical trials soon.

Every year, an estimated 1.9 million people are diagnosed with rectal cancer. It is one of the fastest growing diseases in the world. The rectum is located deep in the lower abdomen, close to the surrounding tissues. That doesn't exactly make surgery easy. Suture leakage is the most common and at the same time the most feared complication of colon and rectal surgery. Such leakage occurs where a new connection between the colon and rectum has been made after the removal of a malignant tumor.

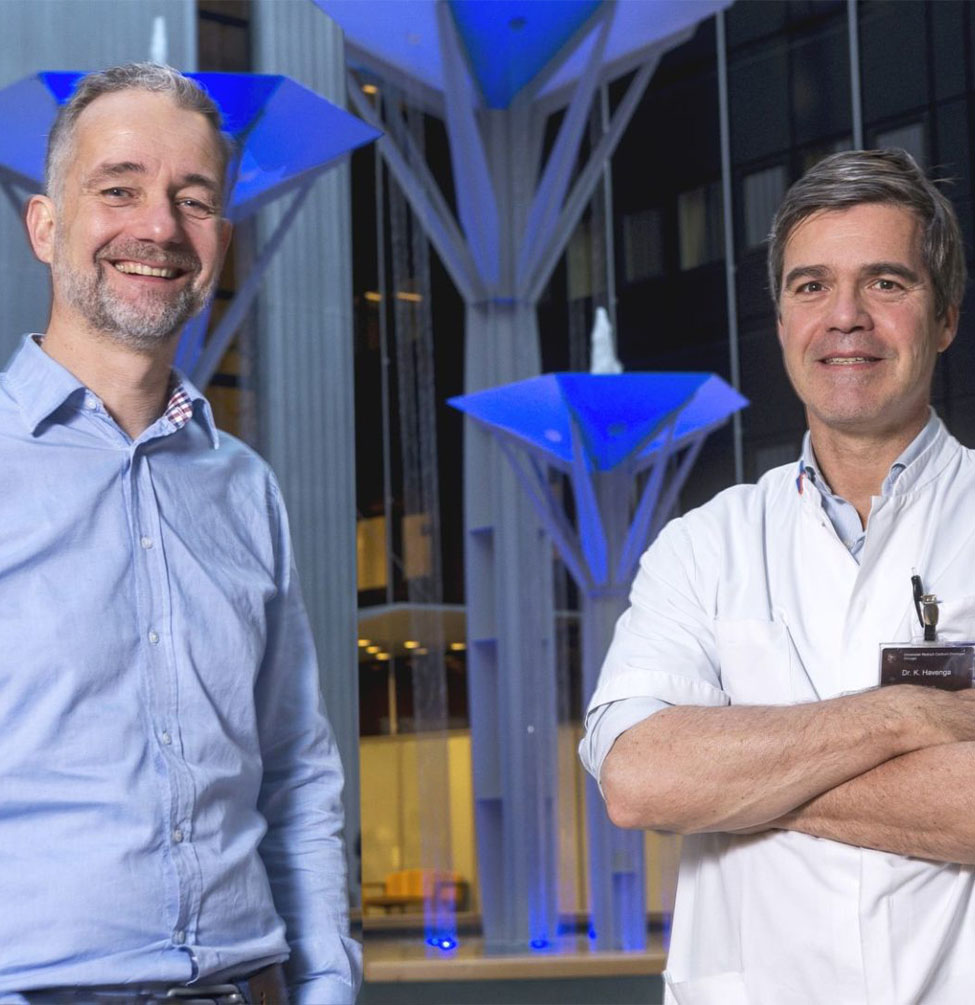

'It is a serious problem that occurs in at least 10% of operations,' says Klaas Havenga, Chief Medical Officer (CMO) of Implican and head of the Gastro-Intestinal Surgery Department at UMCG. 'After 30-30 days, it can even reach as high as 20%. The leakage causes inflammation around the connection. Patients are sick longer as a result, and often follow-up surgery and the placement of a permanent stoma are unavoidable.

Patented technology

Enough reason to look for ways to significantly reduce the risk of seam leakage and, above all, promote wound healing. That is exactly what Klaas has been doing for the past few years. In fact, together with Ivo Kooijman, an experienced innovation professional in the field of medical product development, the surgeon is developing a new patented technique to make a connection between the colon and the rectum. They are doing so under the name Implican, the startup Klaas founded in 2016 with Olf Boesjes (still a shareholder). More about the technique and the development of Implican later.

First, a little background. Because how does making colorectal anastomoses, the medical name for the aforementioned new suture, work these days? 'In currently common suturing techniques, metal staples are used,' explains Ivo Kooijman, CEO of Implican. 'An intestine consists of several layers of tissue. A bacteria-rich mucus layer, a dynamic muscle layer with a strong tissue layer in between. Those staples go right through all the tissue layers and push them together, as it were. This creates a rather granular structure as the wound heals. Whereas, to prevent seam leakage and get a nice and thin healing line, the right tissue layers should actually lie neatly against each other.'

So time for a better alternative to the surgical stapler. All indications are that Implican has figured that out by now. Broadly speaking, what does this new technique look like? 'We use two rings that are placed in both intestinal sections,' Klaas begins his explanation.

'We designed those rings in such a way that they push away specific layers of tissue with a considerable compression force. By completely pushing away the mucus layer and the muscle layer, only the strong intermediate layer remains, the so-called submucosa. This submucosa of both intestinal parts is then compressed and neatly clamped together. To do this properly and safely, we have developed a device. Just outside the ring, the sterile and well-perfused submucosa from above and below lie against each other, allowing the wound to heal quickly and reliably. Because the rings leave the intestines by the natural way, no foreign material remains.'

Start-up ecosystem

1. A nation of start-ups The Netherlands is a top-five start-up hotspot in Europe, with a government committed to supporting the innovation-leaders…

1. A nation of start-ups The Netherlands is a top-five start-up hotspot…

Read more

Life Sciences & Health

1. Europe’s reference region for healthy ageing With a decades-long focus on healthy ageing and prevention, TopDutch is recognized as a four-star…

1. Europe’s reference region for healthy ageing With a decades-long focus on…

Read moreAlways moving forward

For the first few years, innovation was worked on somewhat in the lee. But as the technology began to take shape, Klaas felt the need for someone to act as CEO. After all, he himself had to combine building Implican with a full-time job as a surgeon. That person was found some three years ago in Ivo, who, with his vast experience at renowned organizations in medical product development, proved to be the right man in the right place.

'I keep going until the desired result is achieved,' says Ivo. 'You have to if you are involved in innovation every day. It is especially important to include relevant people in your story. You do have to be open to adjusting your own vision where necessary on the basis of their ideas. Only then can you successfully move an innovation forward. That is without a doubt the most important lesson I have learned over the past 15 years.'

Soon after Ivo strengthened the startup, the first grants were secured. Relatively small amounts, but enough to test some important functions of the device and the rings. A Proof of Concept, or POC for short, to be exact. 'Then we started focusing on developing a Minimum Viable Product, a minimal version of the final product, to validate the technology,' Ivo describes the progress at the time. 'Our goal was to test wound healing when using our technique on two pigs. Simply because a pig inside the abdomen, in terms of size and shapes, is very similar to humans. With the help of funding from the RUG Holding Company and Triade, we eventually succeeded. And how!

Indeed, the tests lived up to all expectations. Every step devised by Klaas and Ivo turned out to be feasible. As a result, the operation went very well and there were no complications even after a few days. 'The wound had healed the way you want a wound to heal,' Ivo emphasizes. 'Any specialist will recognize this way of wound healing as surgical quality. Our technique is, in short, a giant leap forward.'

Preclinical and clinical trials

The promising test results and the added value of the technology did not escape NOM and NextGen Ventures either. They recently decided together to provide Implican with funding. The investment will mainly be used to further develop the technique, with existing and new cooperation partners, and make it suitable for preclinical and clinical testing.

'As early as next year we hope to conduct the first phase 1 studies, studies in which the technique is tested in humans,' Klaas looks ahead. 'But before that happens, we need to make a version that can be sterilized and in which everything is right down to the smallest detail. We are also diligently looking for an experienced project leader with knowledge of applied mechanics, medical devices and product development. The Phase 1 studies will be followed by a larger study to obtain CE registration for medical devices. From then on, we will focus on shaping production optimally. Given the current developments, there is every reason to look to the future with confidence.'

Join TopDutch

So what will be your next move? How will your company join the fight for a healthier population? Contact our network of knowledge-intensive institutions and innovative and entrepreneurial companies. You’ll soon see for yourself how quickly things get done here in the Northern Netherlands.

TopDutch Professional

"*" indicates required fields