Want to take the next step in your green chemistry growth?

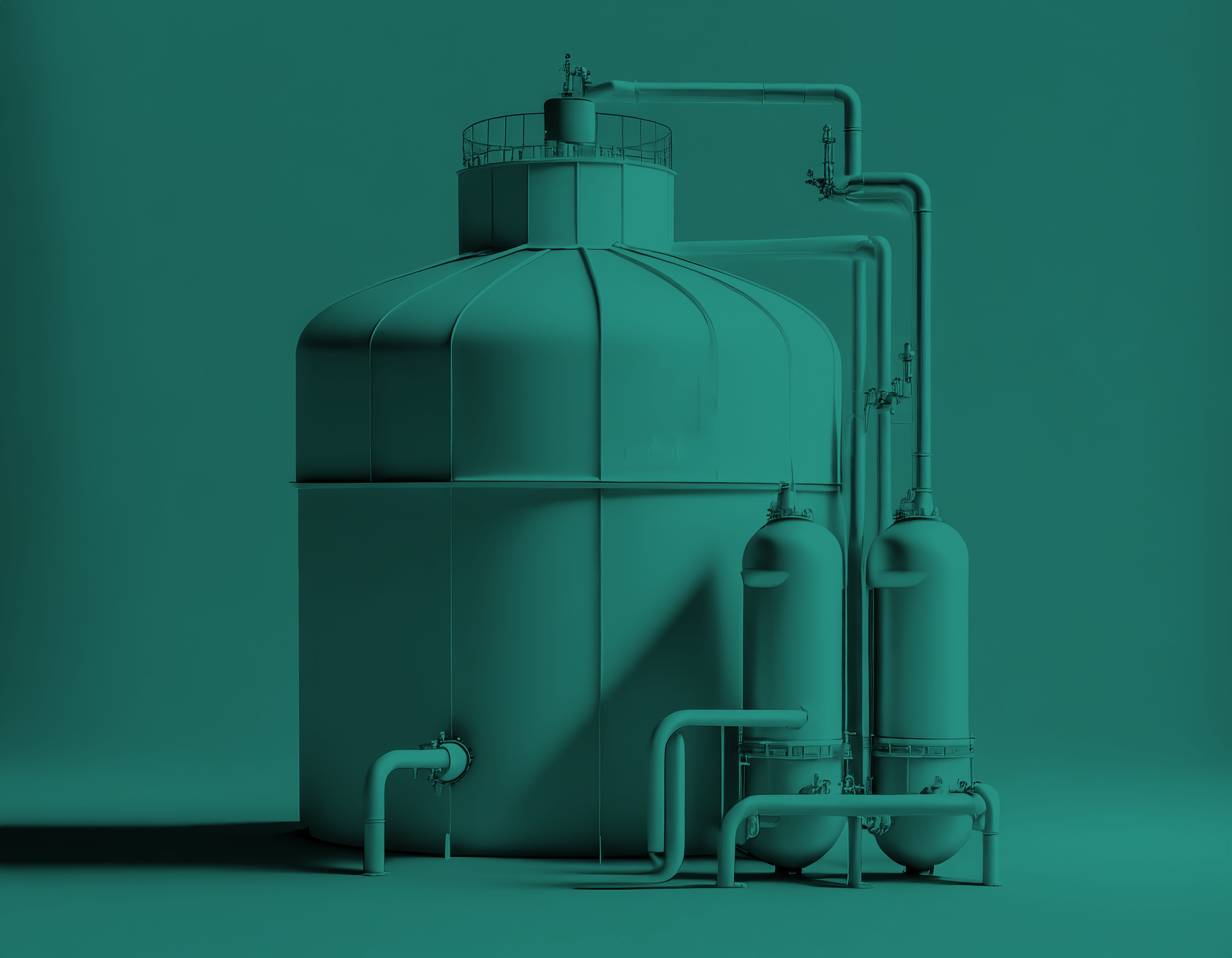

Imagine your business at the world’s first fully green chemical cluster. By 2050, we will be fossil-free, carbon-negative, and have a closed plastics loop — and you can be part of that. In TopDutch, you have all the resources to make your chemical operations green. Developing CO₂ capture systems, recycling all kinds of plastics, building supply chains powered by green feedstocks and energy from wind, solar and hydrogen: join us to change the nature of chemistry.

150+ chemical companies have chosen TopDutch

Green chemistry innovation needs the right ecosystem

Transitioning to a green chemical industry requires the right input: renewable energy, green building blocks, and unconventional thinking. Most regions fall short. They lack reliable access to biomass, green hydrogen, and talent. How can you find the ecosystem that will set you up for green chemistry success?

Your chemical business is bound to succeed in TopDutch

Circtec found the perfect location for their business to grow in the TopDutch region

For our factory, we needed a site near water with proximity to ports in Amsterdam, Rotterdam, and Antwerp. Finding a suitable location was challenging. Delfzijl offered the space we needed

TopDutch resources for your green chemistry success

Green feedstocks

Start with renewable raw materials. Convert locally grown sugar beets and potatoes into biomass read more

Green energy

Power your operations with a stable supply of green energy: our flat coastal region has long been an attractive location for wind farms read more

CO2 feedstock

Develop carbon-to-chemicals technologies alongside companies such as Photanol, which converts CO₂ into organic acids read more

Circular polymers

Recycle plastics, turning waste back into usable, high-quality materials read more

How do we work? The next steps

Success stories from our green chemistry ecosystem

Green building blocks for green chemistry

Green building blocks for green chemistry Wherever you look, you can’t fail to see the results of the chemical industry. Our children’s…

Green building blocks for green chemistry Wherever you look, you can’t fail…

Read more

Transforming old tires into sustainable fuels and chemicals: CIRCTEC choose TopDutch for revolutionary new plant

Transforming old tires into sustainable fuels and chemicals: CIRCTEC choose TopDutch for revolutionary new plant Tires are incredible pieces of technology –…

Transforming old tires into sustainable fuels and chemicals: CIRCTEC choose TopDutch for…

Read more

Why ChainCraft are choosing TopDutch to create circular chemicals from food waste

Why ChainCraft are choosing TopDutch to create circular chemicals from food waste ChainCraft are rejecting palm oil and petroleum and replacing them…

Why ChainCraft are choosing TopDutch to create circular chemicals from food waste…

Read moreCall me back

Please feel free to fill out the “Call Me Back” form below, and we’ll be delighted to get in touch with you at your convenience.